History of Circuit Cable Assembly

Circuit cable assemblies are essential components in the infrastructure of modern electronic and electrical systems. From the rudimentary systems of the early 20th century to the sophisticated, miniaturized solutions of today, the development of circuit cable assembly reflects the broader evolution of electronics and communication technologies. This essay explores the history of circuit cable assembly, examining its origins, technological milestones, industrial applications, and the innovations that have shaped its development over the decades. It’s important to find a good cable assemblies manufacturer.

Early Beginnings: The Age of Telegraphy and Early Electronics (1800s–1920s)

The foundations of circuit cable assembly can be traced back to the 19th century with the invention of the telegraph and early telephone systems. These early communication devices required reliable electrical connections to transmit signals over long distances. In the early 1800s, inventors such as Samuel Morse and Charles Wheatstone developed telegraph systems that used simple conductive wires to carry electrical pulses. While these were not “cable assemblies” in the modern sense, they marked the first instances of structured electrical wiring for communication purposes.

With the invention of the telephone by Alexander Graham Bell in 1876, the demand for organized and insulated wiring increased. Early telephone systems used twisted pair cables to reduce electromagnetic interference, an early insight into cable design that would later become fundamental to data transmission systems.

The early 20th century saw the introduction of vacuum tubes and early radio communication, which required more complex electrical assemblies. As radio receivers and transmitters became more advanced, the need for standardized cable connectors and organized wiring systems began to emerge.

World War II and the Rise of Mass Production (1930s–1940s)

The outbreak of World War II had a profound impact on the development of circuit cable assemblies. The war effort demanded rapid innovation in communication, navigation, and radar systems. Military equipment needed to be rugged, reliable, and easy to repair in the field. This led to the development of standardized wiring harnesses and connectors.

Companies such as Raytheon, Bell Labs, and Western Electric played significant roles in advancing cable assembly technology during this time. The introduction of modular connectors, such as the Amphenol connectors used in military radios and aircraft, allowed technicians to quickly assemble and replace wiring systems.

The war also accelerated the use of color-coded wires, insulation materials like rubber and plastic, and crimping tools. These innovations would lay the groundwork for the mass production of circuit cable assemblies in the post-war era.

The Post-War Boom and the Electronics Revolution (1950s–1970s)

The 1950s and 1960s witnessed a rapid expansion of consumer electronics, from televisions to early computers. With this boom came a greater need for reliable and compact circuit cable assemblies. The introduction of the transistor in 1947, and later the integrated circuit (IC) in the late 1950s, revolutionized the design of electronic devices. Systems became smaller and more complex, requiring precise cable routing and advanced assembly techniques.

During this period, the aerospace and automotive industries began adopting more sophisticated wiring systems. The development of commercial aviation and space exploration—exemplified by NASA’s Apollo program—demanded ultra-reliable cable assemblies. These assemblies had to withstand extreme temperatures, vibrations, and radiation. Companies developed multi-core cables, shielded wires, and flexible circuits to meet these demands.

In industrial settings, cable assemblies were used to connect sensors, actuators, and control systems in automation equipment. Printed circuit boards (PCBs) became the backbone of electronic devices, and cable assemblies served as the crucial interface between different circuit boards and external devices.

The Digital Age and Surface Mount Technology (1980s–1990s)

By the 1980s, the proliferation of personal computers, mobile phones, and digital electronics led to a surge in demand for high-density and high-speed cable assemblies. Surface Mount Technology (SMT) allowed components to be mounted directly onto PCBs, reducing the need for bulky through-hole components and enabling more compact designs.

Flexible flat cables (FFCs) and ribbon cables became popular in this era for connecting internal components in computers and printers. Coaxial cables, originally developed for military use, found widespread adoption in television and networking applications.

At the same time, advancements in manufacturing technology led to the automation of cable assembly processes. Computer-controlled machines could cut, strip, crimp, and test cables with high precision and speed. This improved reliability and reduced labor costs, allowing for large-scale production of cable assemblies.

Modern Era: High-Speed Data, IoT, and Miniaturization (2000s–Present)

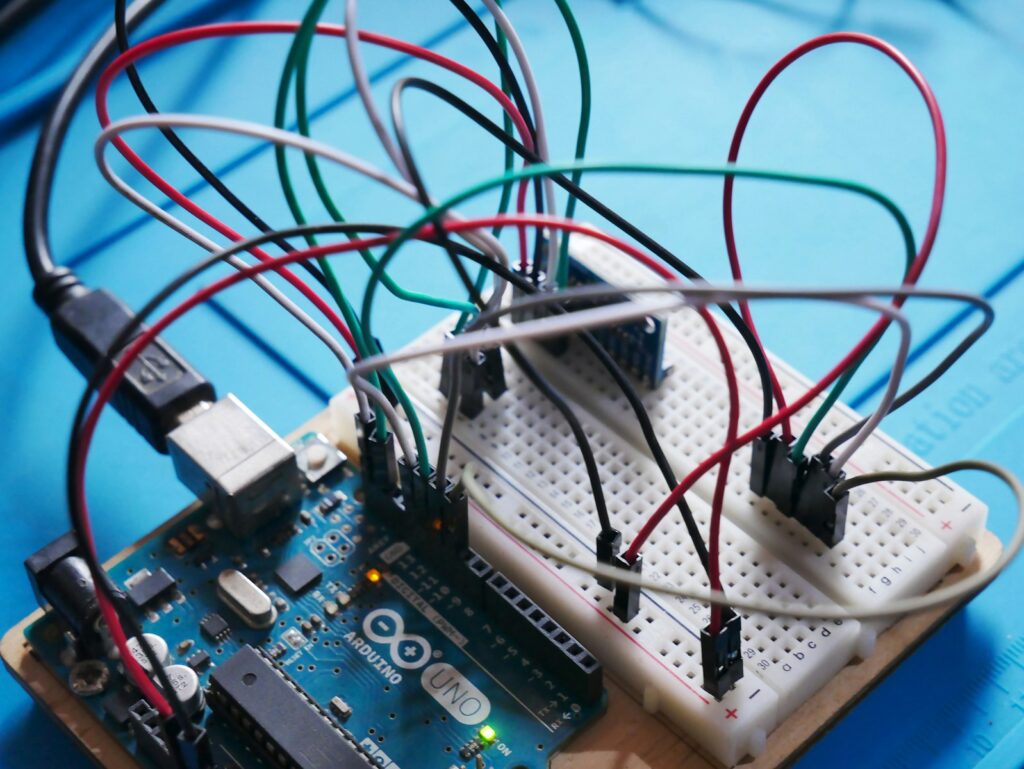

In the 21st century, the digital transformation of society has placed new demands on circuit cable assemblies. Modern applications require cable assemblies that support high-speed data transmission, compact form factors, and harsh environmental tolerances.

The rise of the Internet of Things (IoT), wearable devices, and autonomous vehicles has pushed engineers to design ultra-miniature, lightweight cable assemblies with complex routing. USB-C, HDMI, and Thunderbolt cables exemplify the evolution of high-speed, multifunctional cable assemblies for consumer electronics.

Fiber optic cables, which use light rather than electricity to transmit data, have become essential in telecommunications and data centers. Though technically different from traditional copper cable assemblies, they reflect the same design principles: reliability, signal integrity, and ease of installation.

Meanwhile, medical devices, aerospace systems, and renewable energy installations have imposed new challenges on cable design. Materials science has led to the development of cables with improved fire resistance, chemical resistance, and electromagnetic shielding.

Sustainability has also become a major consideration. Manufacturers are now focusing on recyclable materials, lead-free soldering, and energy-efficient production processes.

The history of circuit cable assembly is a story of continuous innovation, driven by the evolving needs of society and technology. From the simple wired connections of the telegraph era to the sophisticated, automated assemblies used in satellites and smartphones, cable assemblies have remained a vital component of electronic systems. Each era—shaped by war, industry, computing, and connectivity—has contributed to the refinement of materials, methods, and standards.

As we move into a future of quantum computing, AI, and smart infrastructure, the role of circuit cable assembly will remain crucial. Its evolution reflects not only technological progress but also the ingenuity of engineers and manufacturers in meeting the complex challenges of connectivity and reliability in an increasingly electronic world.